Amada type down stroke moving sheet metal press brake bending machine amada

Main Features:

1.Hydraulic system adopts simplified hydraulic system circuit to avoid oil leak and make it easier for maintenance.

2.Hydraulic cylinder is designed in the center axle of the machine. Thus, the tilt rates of the upper working table and the lower working table are minimum when pressurized. So the working accuracy is high.

3.Roller guide moving parts are designed in the center axle of the lower working table. It owns robust sliding surface and moves up-and-down along the two side faces of the hydraulic cylinder, which ensures parallelism between the upper working table and the lower working table.

4.The lower part of the machine is the main machine part designed to improve working efficiency. The stroke of the lower working table can be set easily to the minimum value. Moreover, the bending angle can be set easily and freely by the wheel.

5.Pedal switch is able to control the lower working table speed at will or make it stop, which is easy to achieve bending in line.

6.Mould installation and center correction are achieved by the intermediate plate of the upper working table and the lower die base.

7.The professional numerical control system NC9 or NC10 has touch screen, electrical hand wheel and programming function which is simple and quick.

Technical Parameters:

| Technical specification | RG-10031 | Unit | |

| Nominal pressure | 1000 | KN | |

| Length of table | 3100 | mm | |

| Distance between uprights | 2550 | mm | |

| Throat depth | 400-410 | mm | |

| Stroke of working table | 100-103 | mm | |

| Max open height | 370-375 | mm | |

| Max die setting height | 250-255 | mm | |

| Speed of lower working table | Approaching | 37-47 | mm/s |

| Bending | 7.5-9.2 | mm/s | |

| Returning | 47-55 | mm/s | |

| Number of hydro-cylinder | 3 | piece | |

| Main motor | 7.5 | KW | |

| Machine precision | Slide repeating | ≤±0.01 | mm |

| Slide positioning | ≤±0.02 | mm | |

| Back gauge repeat positioning | ≤±0.02 | mm | |

| Working precision | Work straightness | 0.1/m | mm |

| Bending angle error | <±15 | ′ | |

| Net weight | 6600 | kg | |

| Overall dimension(L*W*H) | 3420*1560*2300 | mm | |

Main configuration:

| No. | Main configuration | Manufacturer |

| 1 | oil pump | Germany Voith Turbo or Japan NACHI |

| 2 | sealingelement | Japan NOK |

| 3 | oiltube | China Taiwan |

| 4 | valve | China mainland |

| 5 | back gauge | China mainland |

| 6 | numerical control system | NC9 Touch screen professional CNC system |

| 7 | servomotor | Mitsubishi, Panasonic |

250ton 4000mm hydraulic CNC pr...

250ton 4000mm hydraulic CNC pr...  80ton 2550mm hydraulic CNC pre...

80ton 2550mm hydraulic CNC pre...  Delem CNC Synchronized Press B...

Delem CNC Synchronized Press B...  Amada type RG60T/2000mm hydrau...

Amada type RG60T/2000mm hydrau...  NC Hydraulic press brake bendi...

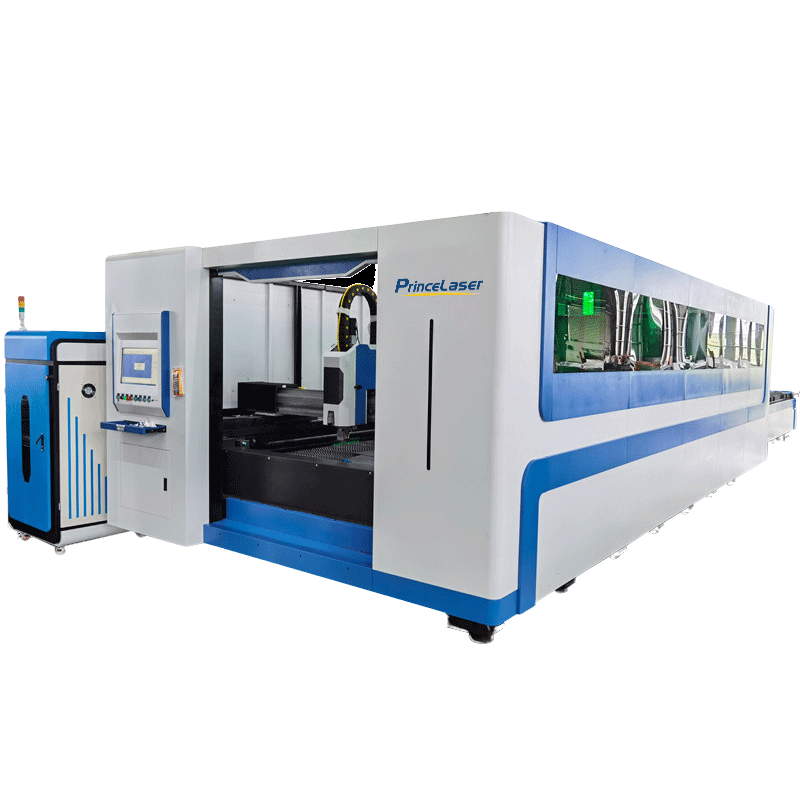

NC Hydraulic press brake bendi...  3000W 4000w Raycus exchangeabl...

3000W 4000w Raycus exchangeabl...  Automatic Coil Feed fiber Lase...

Automatic Coil Feed fiber Lase...  Big table bigg watts full cove...

Big table bigg watts full cove...  1000W 1500W 2000W 3000W 4000W...

1000W 1500W 2000W 3000W 4000W...  1500W 1KW 2KW 3KW Fiber laser ...

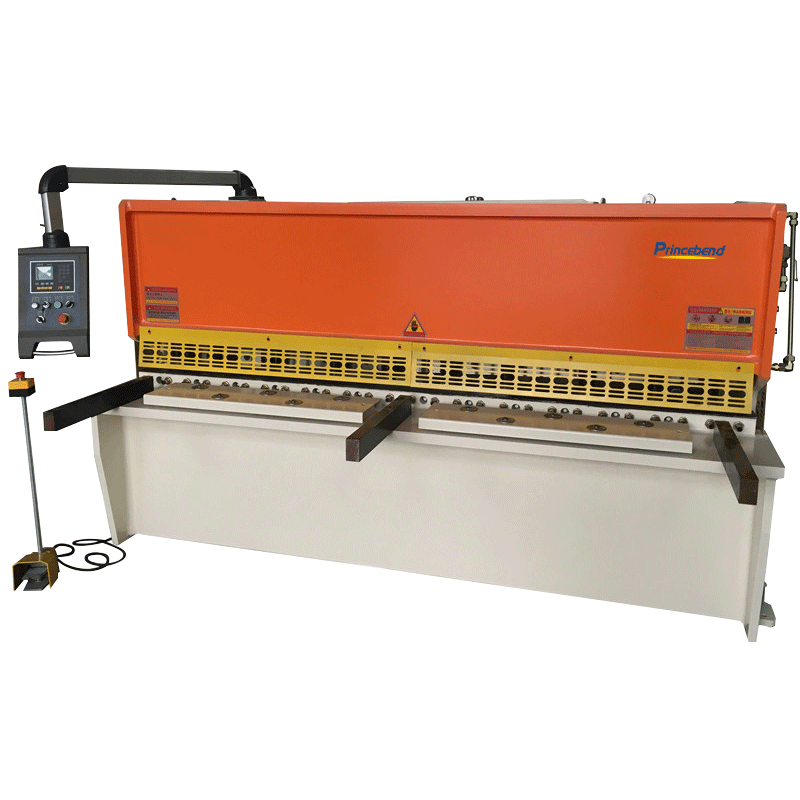

1500W 1KW 2KW 3KW Fiber laser ...  Hydraulic Swing Beam Metal she...

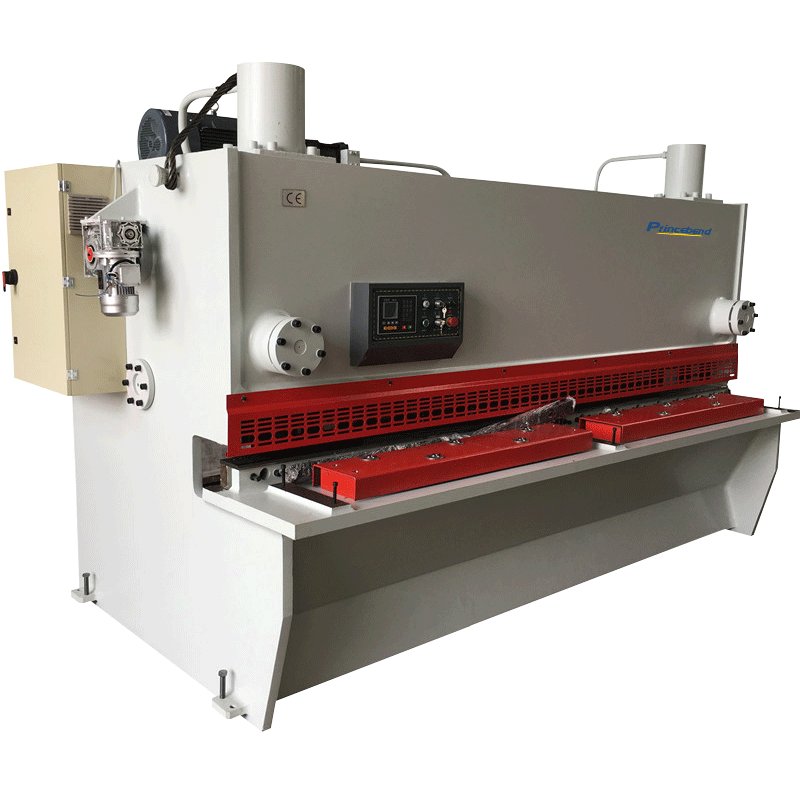

Hydraulic Swing Beam Metal she...  Cnc hyraulic shearing machine

Cnc hyraulic shearing machine  Sheet metal hydraulic guilloti...

Sheet metal hydraulic guilloti...  heavy duty type shearing machi...

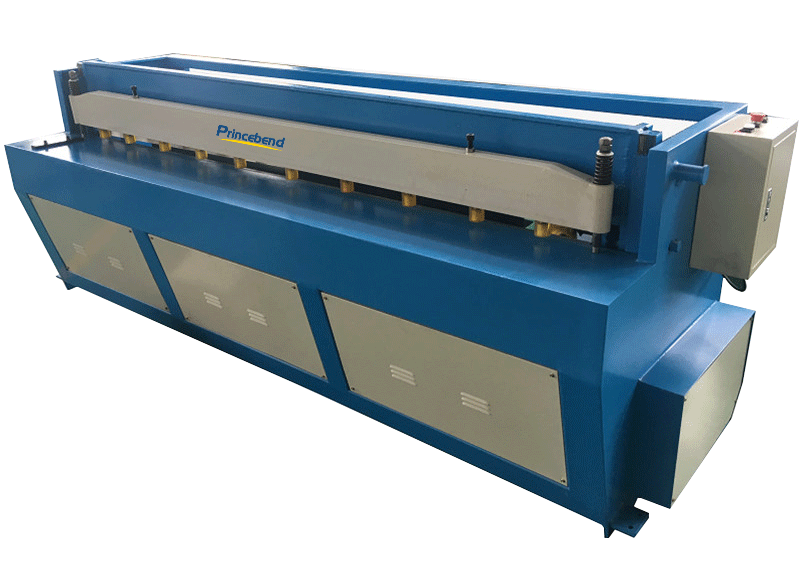

heavy duty type shearing machi...  Metal Electric Shearing Machin...

Metal Electric Shearing Machin...  2500mm Automatic Panel Bender...

2500mm Automatic Panel Bender...  15 Axis Sheet Metal Bending Ce...

15 Axis Sheet Metal Bending Ce...  Automatic Panel Bender Metal P...

Automatic Panel Bender Metal P...  W12 4 rolls plate bending mach...

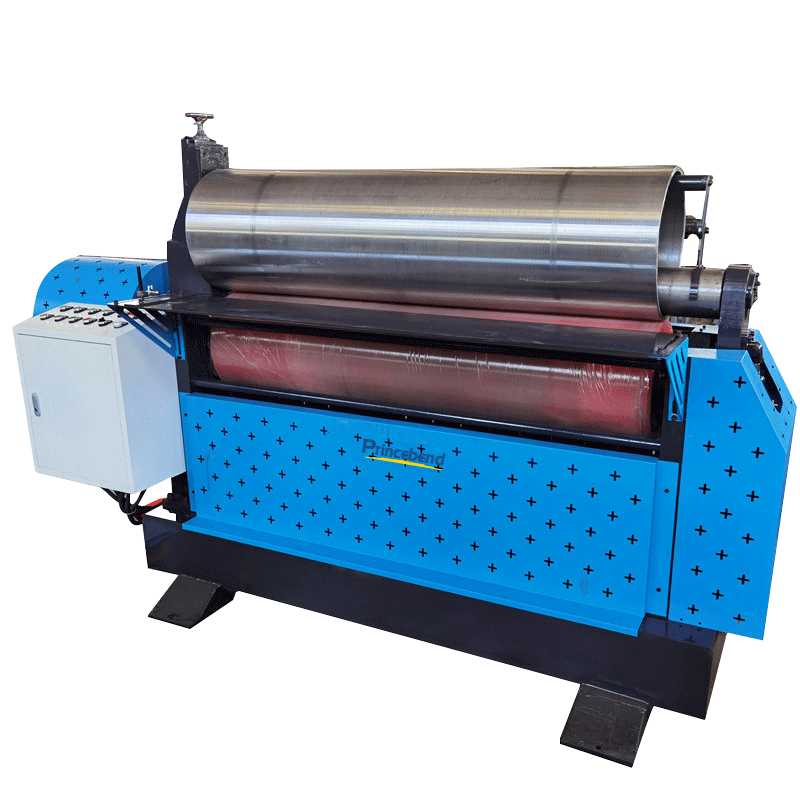

W12 4 rolls plate bending mach...  NC hydraulic W11S 3 roller ste...

NC hydraulic W11S 3 roller ste...  Hydraulic cnc 4 rolls bending ...

Hydraulic cnc 4 rolls bending ...  Heavy metal sheet Four rollers...

Heavy metal sheet Four rollers...  Heavy duty type Two roller pla...

Heavy duty type Two roller pla...