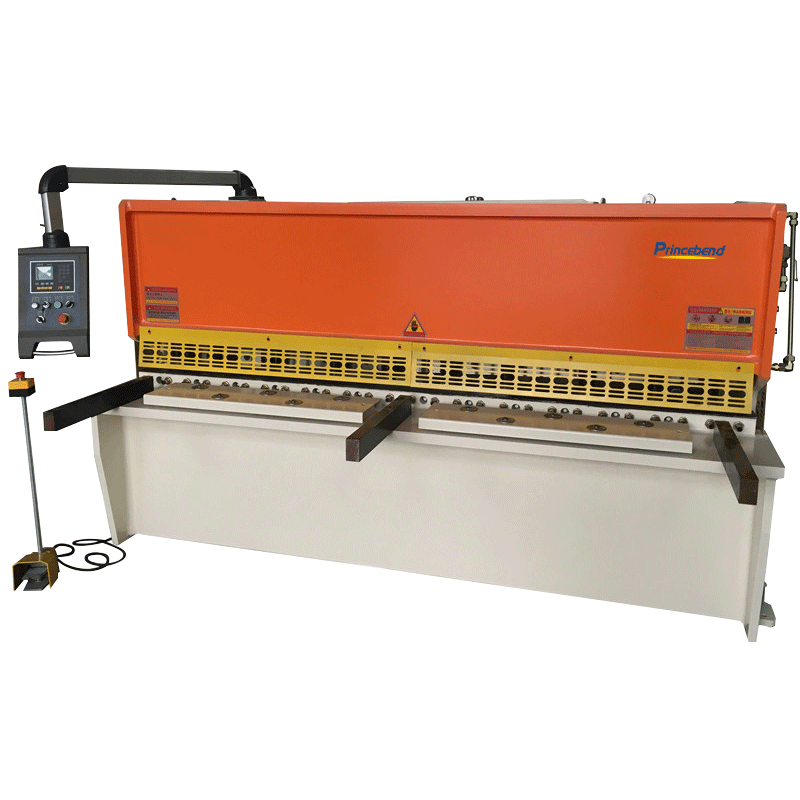

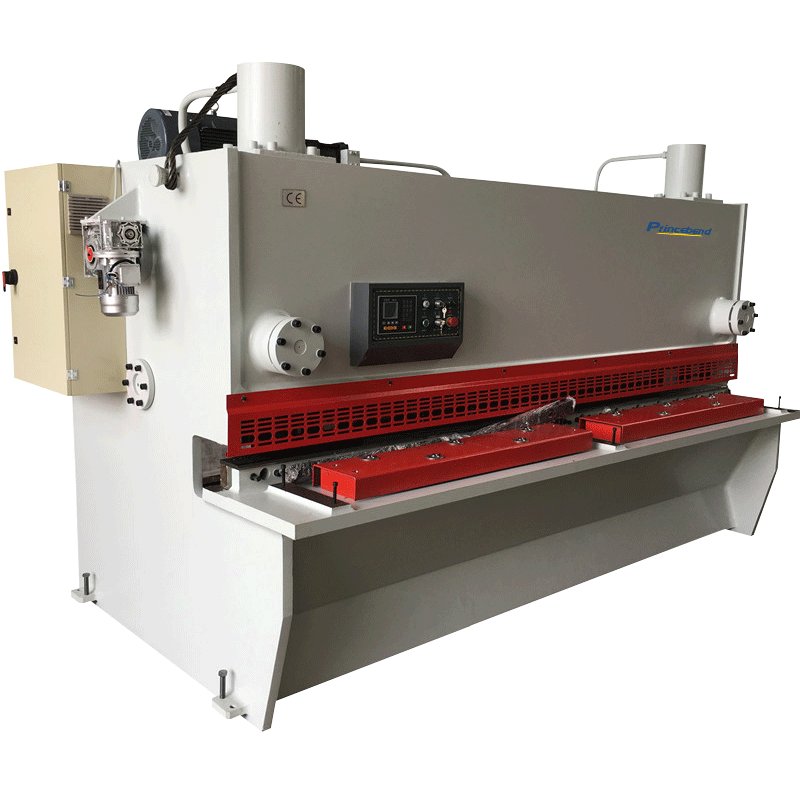

Sheet metal hydraulic guillotine Shearing Machine

Sheet metal hydraulic guillotine Shearing Machine plate Guillotine Shear

Sheet metal hydraulic guillotine Shearing Machine plate Guillotine Shear

video link:

1,Technical specification

| No | Model | Max cut thicknessmm | Max cut lengthmm | Ram Stroken/min | Cutting angle° | Motorkw | Machine Sziemm |

| 1 | 4×2500 | 4 | 2500 | 20-40 | 0.5-1.5 | 5.5 | 3100x1600x1700 |

| 2 | 4×3200 | 4 | 3200 | 20-40 | 0.5-1.5 | 7.5 | 3800x1800x1700 |

| 3 | 6×2500 | 6 | 2500 | 16-35 | 0.5-1.5 | 7.5 | 3150x1650x1700 |

| 4 | 6×3200 | 6 | 3200 | 14-35 | 0.5-1.5 | 7.5 | 3860x1810x1750 |

| 5 | 6×4000 | 6 | 4000 | 10-30 | 0.51.5 | 7.5 | 4630x2030x1940 |

| 6 | 6×5000 | 6 | 5000 | 10-30 | 0.5-1.5 | 11 | 5660x2050x1950 |

| 7 | 6×6000 | 6 | 6000 | 8-25 | 0.5-1.5 | 11 | 6680x2200x2500 |

| 8 | 8×2500 | 8 | 2500 | 14-30 | 0.5-1.5 | 11 | 3170x1700x1700 |

| 9 | 8×3200 | 8 | 3200 | 12-30 | 0.5-1.5 | 11 | 3870x1810x1780 |

| 10 | 8×4000 | 8 | 4000 | 10-25 | 0.5-1.5 | 11 | 4680x1900x1860 |

| 11 | 8×5000 | 8 | 5000 | 10-25 | 0.5-1.5 | 15 | 5680x2250x2200 |

| 12 | 8×6000 | 8 | 6000 | 8-20 | 0.5-1.5 | 15 | 6800x2350x2700 |

| 13 | 10×2500 | 10 | 2500 | 10-25 | 0.5-2.0 | 15 | 3270x1730x1800 |

| 14 | 10×3200 | 10 | 3200 | 9-25 | 0.5-2.0 | 15 | 3990x2250x2200 |

| 15 | 10×4000 | 10 | 4000 | 6-20 | 0.5-2.0 | 15 | 4720x2490x2500 |

| 16 | 10×5000 | 10 | 5000 | 7-20 | 0.5-2.0 | 22 | 5720x2600x2800 |

| 17 | 10×6000 | 10 | 6000 | 6-20 | 0.5-2.0 | 30 | 6720x2500x2550 |

| 18 | 12×2500 | 12 | 2500 | 10-25 | 0.5-2.0 | 15 | 3270x1730x1800 |

| 19 | 12×3200 | 12 | 3200 | 9-25 | 0.5-2.0 | 15 | 3990x2250x2200 |

| 20 | 12×4000 | 12 | 4000 | 6-20 | 0.5-2.0 | 15 | 4720x2490x2500 |

| 21 | 12×5000 | 12 | 5000 | 7-20 | 0.5-2.0 | 22 | 5720x2600x2800 |

| 22 | 12×6000 | 12 | 6000 | 6-20 | 0.5-2.0 | 30 | 6720x2500x2550 |

| 23 | 12×7000 | 12 | 7000 | 6-20 | 0.5-2.0 | 37 | 7800x2600x3200 |

| 24 | 12×8000 | 12 | 8000 | 6-20 | 0.5-2.0 | 45 | 9100x2800x3400 |

| 25 | 12×10000 | 12 | 10000 | 4-18 | 0.5-2.0 | 55 | 11100x3200x3900 |

| 26 | 12×12000 | 12 | 12000 | 4-18 | 0.5-2.0 | 2×37 | 13200x3950x4800 |

| 27 | 16×2500 | 16 | 2500 | 9-20 | 0.5-2.5 | 22 | 3320x2100x2200 |

| 28 | 16×3200 | 16 | 3200 | 8-20 | 0.5-2.5 | 22 | 4120x2150x2300 |

| 29 | 16×4000 | 16 | 4000 | 8-15 | 0.5-2.5 | 22 | 4760x1900x2560 |

| 30 | 16×5000 | 16 | 5000 | 7-15 | 0.5-2.5 | 30 | 5760x2200x2750 |

| 31 | 16×6000 | 16 | 6000 | 6-15 | 0.5-2.5 | 37 | 6880x2480x3000 |

| 32 | 16×8000 | 16 | 8000 | 5-15 | 0.5-2.5 | 55 | 9120x3000x3800 |

| 33 | 16×10000 | 16 | 10000 | 4-15 | 0.5-3.0 | 2×37 | 11200x3400x4000 |

| 34 | 16×12000 | 16 | 12000 | 3-12 | 0.5-3.0 | 2×45 | 13300x4300x5800 |

| 35 | 20×2500 | 20 | 2500 | 7-20 | 0.5-3.0 | 30 | 3300x2050x2440 |

| 36 | 20×3200 | 20 | 3200 | 6-20 | 0.5-3.0 | 30 | 4000x2160x2540 |

| 37 | 20×4000 | 20 | 4000 | 5-15 | 0.5-3.0 | 30 | 4930x2300x2710 |

| 38 | 20×5000 | 20 | 5000 | 4-15 | 0.5-3.0 | 55 | 5860x2400x3150 |

| 39 | 20×6000 | 20 | 6000 | 4-15 | 0.5-3.0 | 55 | 6100x2650x3375 |

| 40 | 20×8000 | 20 | 8000 | 4-15 | 1.0-2.5 | 2×37 | 9120x3400x3800 |

| 41 | 20×10000 | 20 | 10000 | 4-14 | 1.0-2.5 | 2×45 | 11200x4300x5800 |

| 42 | 20×12000 | 20 | 12000 | 3-12 | 1.0-2.5 | 2×55 | 13380x4500x6100 |

| 43 | 25×2500 | 25 | 2500 | 6-15 | 1.0-3.5 | 37 | 3300x2000x2650 |

| 44 | 25×3200 | 25 | 3200 | 5-15 | 1.0-3.5 | 37 | 3970x2100x2865 |

| 45 | 25×4000 | 25 | 4000 | 4-12 | 1.0-3.5 | 45 | 4780x2500x3150 |

| 46 | 25×5000 | 25 | 5000 | 4-12 | 1.5-3.5 | 55 | 6100x2880x3550 |

| 47 | 25×6000 | 25 | 6000 | 3-12 | 1.5-3.0 | 55 | 7200x3000x3850 |

| 48 | 25×8000 | 25 | 8000 | 3-12 | 1.5-3.0 | 2×37 | 9300x3500x4300 |

| 49 | 30×2500 | 30 | 2500 | 4-12 | 1.5-3.5 | 55 | 3500x2300x3200 |

| 50 | 30×3200 | 30 | 3200 | 4-12 | 1.5-3.5 | 55 | 4380x2600x3450 |

| 51 | 30×4000 | 30 | 4000 | 3-12 | 1.5-3.5 | 55 | 5300x3000x3600 |

| 52 | 30×6000 | 30 | 6000 | 3-12 | 1.5-3.0 | 2×37 | 7300x3800x4200 |

| 53 | 40×2500 | 40 | 2500 | 4-10 | 2.0-4.0 | 55 | 3900x2550x3500 |

| 54 | 40×3200 | 40 | 3200 | 3-10 | 2.0-4.0 | 55 | 4600x2900x3750 |

| 55 | 40×4000 | 40 | 4000 | 3-10 | 2.0-4.0 | 2×45 | 5380x3300x4200 |

| 56 | 50×2500 | 50 | 2500 | 3-10 | 2.0-4.0 | 2×55 | 4000x3300x4200 |

| 57 | 50×3200 | 50 | 3200 | 3-10 | 2.0-4.0 | 3×90 | 4700x3600x4500 |

| 58 | 60×3200 | 60 | 3200 | 2-8 | 2.0-4.0 | 4×90 | 4900x3800x4900 |

2,Features of this machine

1.The second generation of shear.

2.Welded steel plate construction, heating to eliminate stress,with high strength and good rigidity.

3.Advanced integrated hydraulic system with and excellent reliabitity quality.

4.Rapidly,accurately and conveniently adjusting the blade clearance by motor

5.The adjustable rake angle can minimize plate deformation.

6.As the cutting beam has been designed in inner-inclined structure,it is easy for plates to fall down and the accuracy of products can be also guaranteed.

7.Shearing in sections,shadow-line cutting.

8.Counter for the motorized back gauge.

9.Back support device (optional).

3.Machine key components list

| No. | Name | Brand | Location |

| 1 | Motor | Siemens | Germany |

| 2 | Electrics | SCHNEIDER | France |

| 3 | Oil Cylinder | Wuyang | Anhui, China |

| 4 | Seal ring | NOK | Japan |

| 5 | Pump | Lifeng | China |

| 6 | Hydraulic system | Bosch | Germany |

| 7 | Valves | Bosch | Germany |

| 8 | Controller | Estun E21 | China Estun |

| 9 | Blade | 6CrW2Si | Jinshan, Shanghai |

| Equipment’s working environment: 2.1 Power supply:3Ph AC 220V ± 10% 60HZ ± (optional to site) 2.2 ambient temperature:-10 ℃ ~ 45 ℃ 2.3 Relative Humidity: ≤ 85%The back gauge structure(our patent) |

We can also change the components according to your demand.

4.Attachment With the machine

| No | Items | parameters | remarks |

| 1 | Upper Down blade | 2 | set |

| 3 | Bolt &Nut | 8 | |

| 4 | feet nut washer | 4 | |

| 5 | Allen wrench&Grease Gun | 1 set | 3 to 14 mm (maintenance tool) |

| 6 | technical documents | certificate of the product, including operation and maintenance manual, electrical, hydraulic schematics, purchased parts inventory, basic maps, packing list. |

250ton 4000mm hydraulic CNC pr...

250ton 4000mm hydraulic CNC pr...  80ton 2550mm hydraulic CNC pre...

80ton 2550mm hydraulic CNC pre...  Delem CNC Synchronized Press B...

Delem CNC Synchronized Press B...  Amada type RG60T/2000mm hydrau...

Amada type RG60T/2000mm hydrau...  NC Hydraulic press brake bendi...

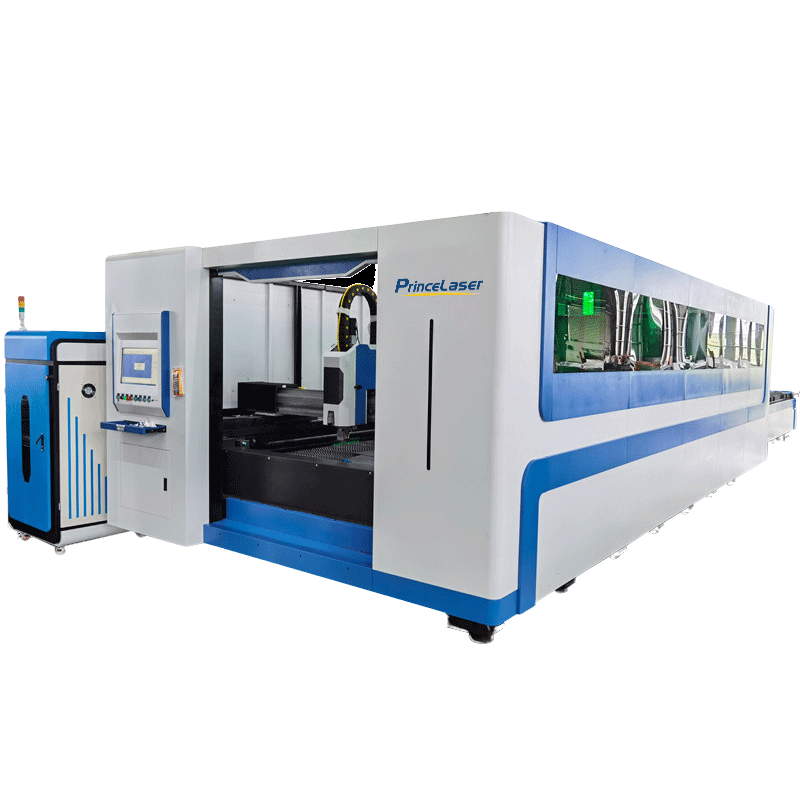

NC Hydraulic press brake bendi...  3000W 4000w Raycus exchangeabl...

3000W 4000w Raycus exchangeabl...  Automatic Coil Feed fiber Lase...

Automatic Coil Feed fiber Lase...  Big table bigg watts full cove...

Big table bigg watts full cove...  1000W 1500W 2000W 3000W 4000W...

1000W 1500W 2000W 3000W 4000W...  1500W 1KW 2KW 3KW Fiber laser ...

1500W 1KW 2KW 3KW Fiber laser ...  Hydraulic Swing Beam Metal she...

Hydraulic Swing Beam Metal she...  Cnc hyraulic shearing machine

Cnc hyraulic shearing machine  Sheet metal hydraulic guilloti...

Sheet metal hydraulic guilloti...  heavy duty type shearing machi...

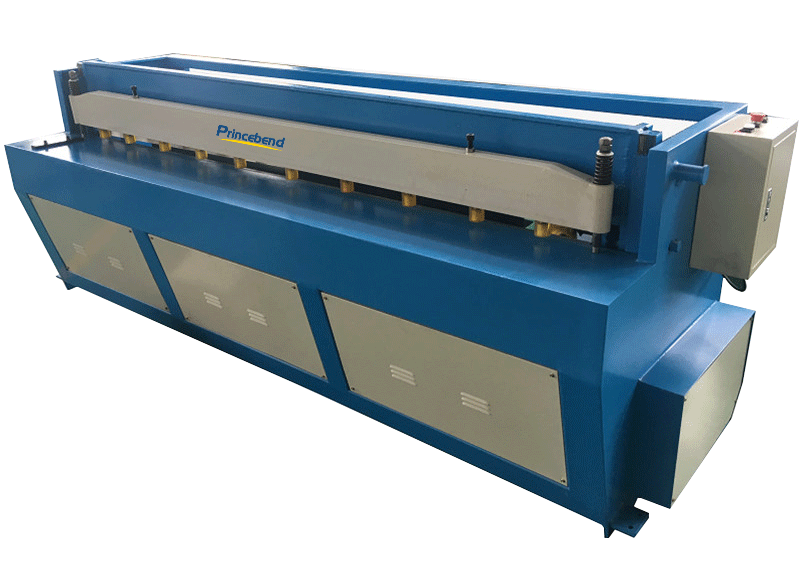

heavy duty type shearing machi...  Metal Electric Shearing Machin...

Metal Electric Shearing Machin...  2500mm Automatic Panel Bender...

2500mm Automatic Panel Bender...  15 Axis Sheet Metal Bending Ce...

15 Axis Sheet Metal Bending Ce...  Automatic Panel Bender Metal P...

Automatic Panel Bender Metal P...  W12 4 rolls plate bending mach...

W12 4 rolls plate bending mach...  NC hydraulic W11S 3 roller ste...

NC hydraulic W11S 3 roller ste...  Hydraulic cnc 4 rolls bending ...

Hydraulic cnc 4 rolls bending ...  Heavy metal sheet Four rollers...

Heavy metal sheet Four rollers...  Heavy duty type Two roller pla...

Heavy duty type Two roller pla...