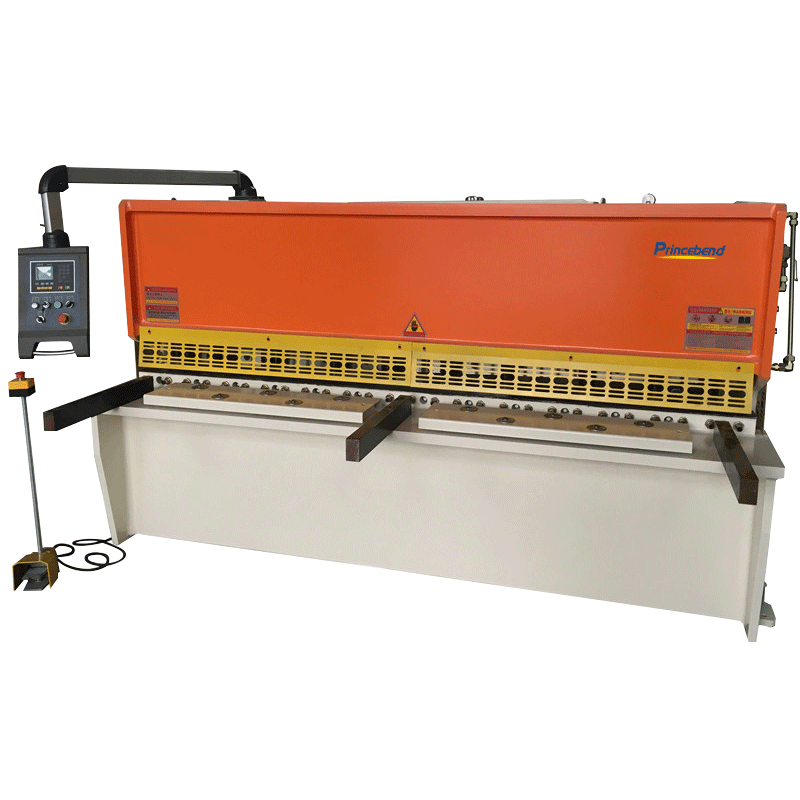

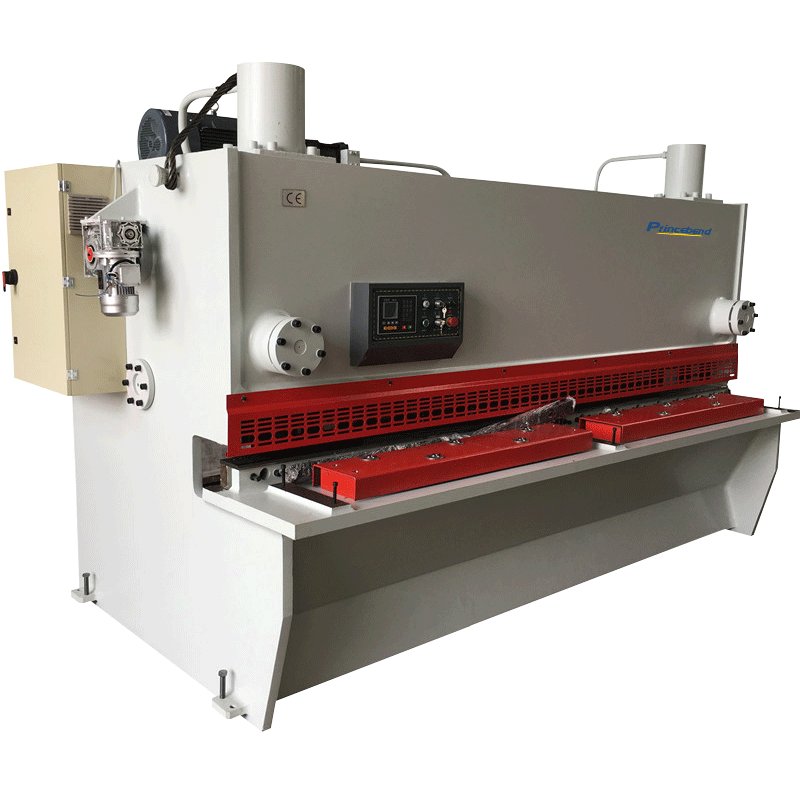

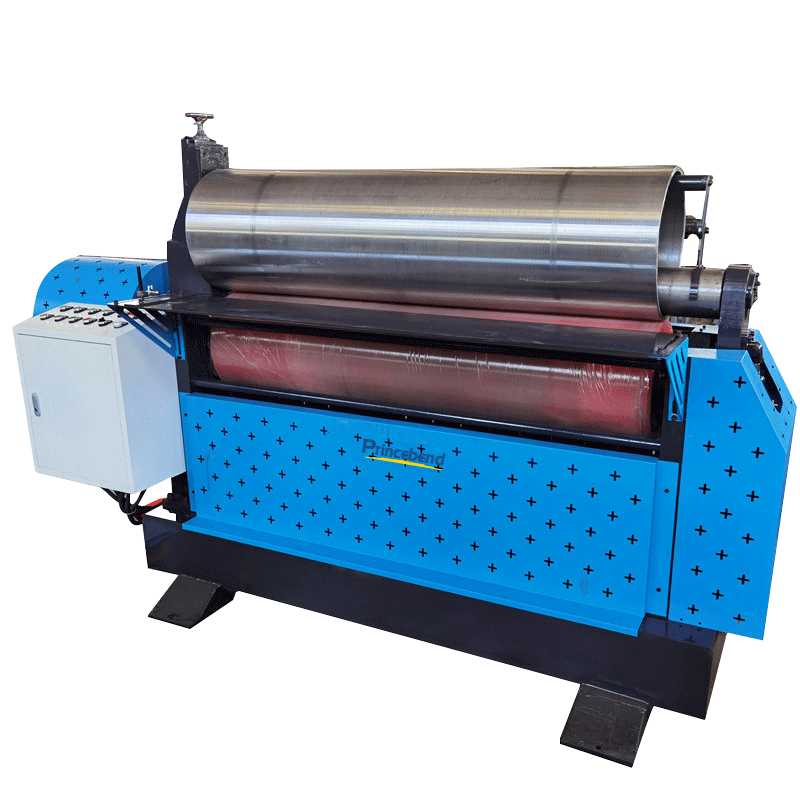

Hydraulic Swing Beam Metal shearing machine

Totally EU streamlined design,Monoblock by welding robots & aparatus and stress relief process by Annealing treatment.

2.Adopt integrated hydraulic system, more reliable and easy for maintenance.and the hydraulic system from Bosch-Rexroth,Germany,

Hydraulic Swing Beam Metal shearing machine

Video link :

Main features:

Main Features:

1.Totally EU streamlined design,Monoblock by welding robots & aparatus and stress relief process by Annealing treatment.

2.Adopt integrated hydraulic system, more reliable and easy for maintenance.and the hydraulic system from Bosch-Rexroth,Germany,

3.The Hydraulic Guillotine is a Swing Beam Action machine which is produced in a variety of cutting lengths and capacity.

4.The distance of the backgauge is adjusted by the motor and is well adjustment is displayed by E21with Delta inverter.

5.Equipped with lighting-alignment, so as to align when shearing. The stroke of knife beam can be adjusted in stepless mode.

6.Safe fence and the electric inter locker have been designed for the machine to ensure the operation safety to CE regulation.

Standard Equipment:

Estun E21sNC controlSystem

PoweredBack gaugeX-axis

DELTAInvertercontrolled back gauge

HIWIN Ball screws & Polished rodwith 0,05mm accuracy.

Squaring Arm and Front Support Arms

Germany Bosch-Rexroth Hydraulic

Germany EMB Tubing connector

Germany Siemens Main Motor

Telemecanique/SchneiderElectrics

Hydraulic &Electrical overload protection

Cutting Line Illumination and wire for shadow line cutting

Top blade with two cutting edges and bottom blade with four cutting edges.(6CrW2Si)

Safety Equipment:

Safety Standards(2006/42/EC):1.EN 12622:2009 + A1:2013 2.EN ISO 12100:2010 3.EN 60204-1:2006+A1:2009

Front finger Protection(Safety light curtain)

South Korea Kacon Foot Switch(Level 4 of safety)

Back metal safe fencewith CE standards

Safety relay with Monitor the pedal switch and safety protection4,Main Configuration:

Serial No. Part Description Brief instruction/ Orignal Other 1- NC Control system ■E21s NC System□E10s NC System 2- Electrical components Schneider Electrical from French Travel switch & Limit switch 3- Main Motor Siemens from Germany Brand 4- BackGauge & RAM Drive Inverter from Taiwan delta Accurate positioning control 5- Foot switch KACON from South Korea 6- Hydraulic System Bosch-Rexroth form Germany Sealing Element PARKER from U.S.A Brand 7- Tubing connector EMB form Germany Brand 8- Ball screw/ Polished rod HIWIN from TaiWan Brand 2.Equipment 1- Pneumatic sheet support system □Yes■No 2- Rear sheet sliding plates ■Yes □No Fixed type(metal) 3- Angle Gauge □Yes■No 4- Squaring Arm(800mm) ■Yes □No 5- Inverter accurate control ■Yes □No 6- Light curtains for finger Protection □Yes■No Reset button 7- Back safety Sensors □Yes■No 8- Back metal fence Safety ■Yes □No 9- Safety standards ■CE □CSA □NR-12 □OSHA 5,Main specifications:

| Shearing thickness | Shearing width | Number of stroke mm | Backgauge range mm | Shearing angler | Backgauge range mm | Motor power KW | |

| 6×2500 | 6 | 2500 | 16~35 | 20-600 | 30’-1°30 | 600 | 7.5 |

| 6×3200 | 6 | 3200 | 14~35 | 20-600 | 30’-1°30 | 600 | 7.5 |

| 6×4000 | 6 | 4000 | 10~30 | 20-600 | 30’-1°30 | 600 | 7.5 |

| 6×5000 | 6 | 5000 | 10~30 | 20-800 | 30’-1°30 | 800 | 11 |

| 6×6000 | 6 | 6000 | 8~25 | 20-800 | 30’-1°30 | 800 | 11 |

| 8×2500 | 8 | 2500 | 14~30 | 20-600 | 30’-1°30 | 600 | 11 |

| 8×3200 | 8 | 3200 | 12~30 | 20-600 | 30’-2° | 600 | 11 |

| 8×4000 | 8 | 4000 | 10~25 | 20-600 | 30’-2° | 600 | 11 |

| 8×5000 | 8 | 5000 | 10~25 | 20-800 | 30’-2° | 800 | 15 |

| 8×6000 | 8 | 6000 | 8~20 | 20-800 | 30’-2° | 800 | 15 |

| 12×2500 | 12 | 2500 | 12~25 | 20-800 | 30’-2° | 800 | 15 |

| 12×3200 | 12 | 3200 | 12~25 | 20-800 | 30’-2° | 800 | 15 |

| 12×4000 | 12 | 4000 | 8~20 | 20-800 | 30’-2° | 800 | 15 |

| 12×5000 | 12 | 5000 | 8~20 | 20-800 | 30’-2° | 800 | 22 |

| 12×6000 | 12 | 6000 | 6~20 | 20-1000 | 30’-2° | 1000 | 30 |

| 16×2500 | 12 | 2500 | 12~20 | 20-800 | 30’-1°30 | 800 | 22 |

| 16×3200 | 16 | 3200 | 12~20 | 20-800 | 30’-1°30 | 800 | 22 |

| 16×4000 | 16 | 4000 | 8~15 | 20-800 | 30’-1°30 | 800 | 22 |

| 16×5000 | 16 | 5000 | 8~15 | 20-1000 | 30’-1°30 | 1000 | 30 |

| 16×6000 | 16 | 6000 | 6~15 | 20-1000 | 30’-1°30 | 1000 | 37 |

| 20×2500 | 20 | 2500 | 10~20 | 20-800 | 30’-3° | 800 | 30 |

| 20×3200 | 20 | 3200 | 10~20 | 20-800 | 30’-3° | 800 | 30 |

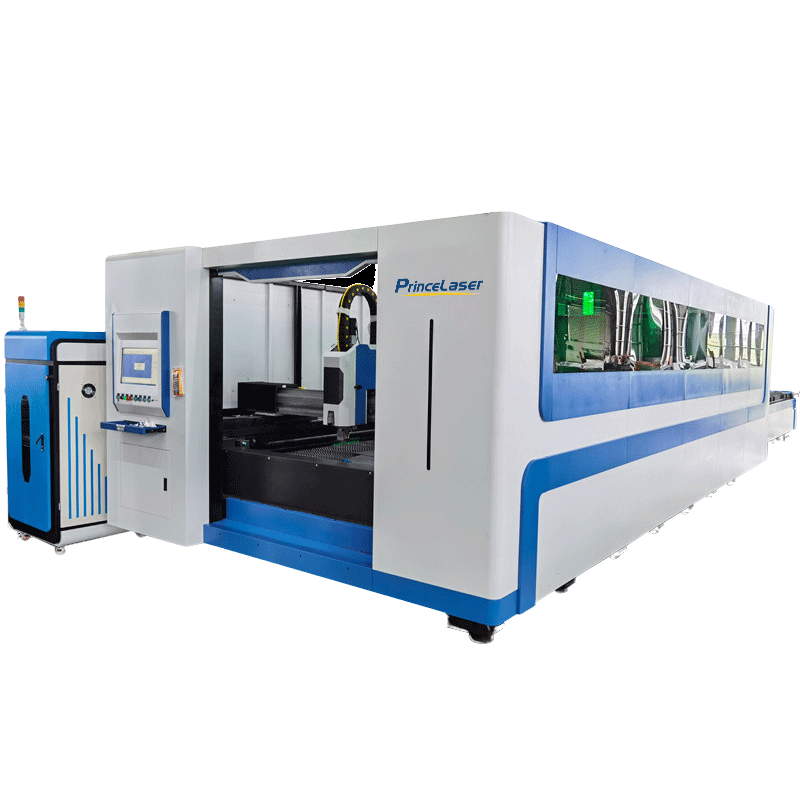

1, photoelectric conversion efficiency can reach 30%, two times that of CO2;

2, less consumption of power source, CO2 is 20% ~ 30%;

3, no laser working gas, can save a lot of laser maintenance cost;

4, optical fiber transmission, without reflection lens, do not need to adjust the light path.

250ton 4000mm hydraulic CNC pr...

250ton 4000mm hydraulic CNC pr...  80ton 2550mm hydraulic CNC pre...

80ton 2550mm hydraulic CNC pre...  Delem CNC Synchronized Press B...

Delem CNC Synchronized Press B...  Amada type RG60T/2000mm hydrau...

Amada type RG60T/2000mm hydrau...  NC Hydraulic press brake bendi...

NC Hydraulic press brake bendi...  3000W 4000w Raycus exchangeabl...

3000W 4000w Raycus exchangeabl...  Automatic Coil Feed fiber Lase...

Automatic Coil Feed fiber Lase...  Big table bigg watts full cove...

Big table bigg watts full cove...  1000W 1500W 2000W 3000W 4000W...

1000W 1500W 2000W 3000W 4000W...  1500W 1KW 2KW 3KW Fiber laser ...

1500W 1KW 2KW 3KW Fiber laser ...  Hydraulic Swing Beam Metal she...

Hydraulic Swing Beam Metal she...  Cnc hyraulic shearing machine

Cnc hyraulic shearing machine  Sheet metal hydraulic guilloti...

Sheet metal hydraulic guilloti...  heavy duty type shearing machi...

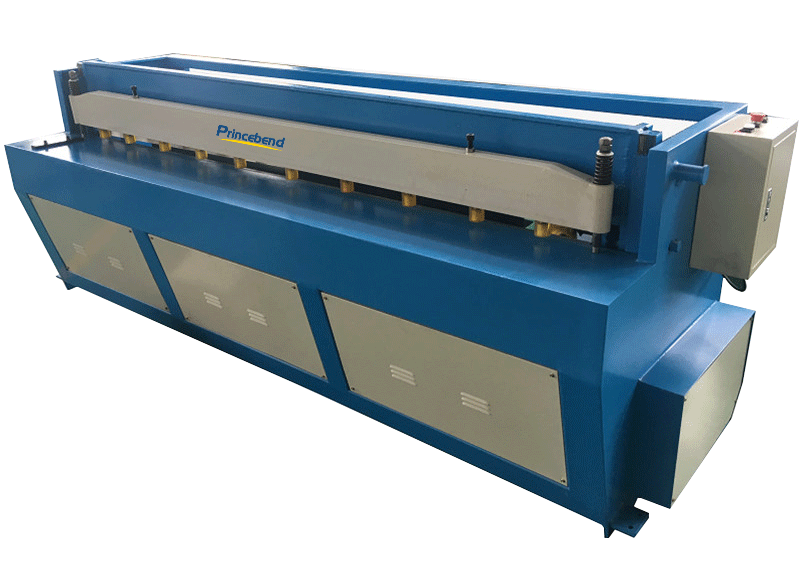

heavy duty type shearing machi...  Metal Electric Shearing Machin...

Metal Electric Shearing Machin...  2500mm Automatic Panel Bender...

2500mm Automatic Panel Bender...  15 Axis Sheet Metal Bending Ce...

15 Axis Sheet Metal Bending Ce...  Automatic Panel Bender Metal P...

Automatic Panel Bender Metal P...  W12 4 rolls plate bending mach...

W12 4 rolls plate bending mach...  NC hydraulic W11S 3 roller ste...

NC hydraulic W11S 3 roller ste...  Hydraulic cnc 4 rolls bending ...

Hydraulic cnc 4 rolls bending ...  Heavy metal sheet Four rollers...

Heavy metal sheet Four rollers...  Heavy duty type Two roller pla...

Heavy duty type Two roller pla...