CNC Shearing Machine to Improve Production Efficiency

Date: 2020-10-20 Categories: Industry News Hits: 985

CNC shearing machine is a kind of efficient metal shearing equipment controlled by computer numerical control system. It is widely used in sheet metal processing, machinery manufacturing and construction industries. Compared with traditional shearing machines, CNC shearing machine can achieve higher shearing accuracy and stronger automation functions, and can adapt to complex production needs.

Through the precise adjustment of the CNC system, the operator can quickly set the shearing angle, shearing length and shearing times, significantly improving production efficiency and processing quality. At the same time, CNC shearing machine also have strong flexibility and can handle metal plates of different thicknesses and materials. They are widely used in the processing of steel, aluminum alloy and other materials.

Improvement of precision and performance of CNC shearing machine

1. Advanced CNC system and software optimization: Modern CNC shearing machine use more precise and intelligent control systems. Advanced CNC systems can not only accurately control the length, angle and gap of shearing, but also optimize the shearing path and speed through algorithms to minimize errors.

2. Servo drive technology: Servo drive technology is an important factor in improving the accuracy of CNC shearing machine. By using servo motors to control the shearing action, more precise angle and position control can be achieved, reducing errors in mechanical transmission.

3. Closed-loop feedback control system: The closed-loop feedback control system can monitor the working status of the CNC shearing machine in real time and make adjustments.

4. High-rigidity body and optimized mechanical structure: The body rigidity of the CNC shearing machine is crucial to its accuracy and stability. .

5. Precision machining of tools and workbenches: The accuracy and durability of tools directly affect the shearing quality.

6. Laser measurement and automatic correction technology: The application of laser measurement technology in CNC shearing machine has further improved the shearing accuracy.

7. Efficient lubrication and cooling system: The design of lubrication and cooling system also has a great impact on the stability and precision of CNC shearing machine. By optimizing the lubrication system, the friction coefficient between the components is kept at the most suitable level, reducing the precision fluctuation caused by friction; the cooling system can keep the temperature of the equipment stable during long-term operation and prevent processing errors caused by thermal expansion.

250ton 4000mm hydraulic CNC pr...

250ton 4000mm hydraulic CNC pr...  80ton 2550mm hydraulic CNC pre...

80ton 2550mm hydraulic CNC pre...  Delem CNC Synchronized Press B...

Delem CNC Synchronized Press B...  Amada type RG60T/2000mm hydrau...

Amada type RG60T/2000mm hydrau...  NC Hydraulic press brake bendi...

NC Hydraulic press brake bendi...  3000W 4000w Raycus exchangeabl...

3000W 4000w Raycus exchangeabl...  Automatic Coil Feed fiber Lase...

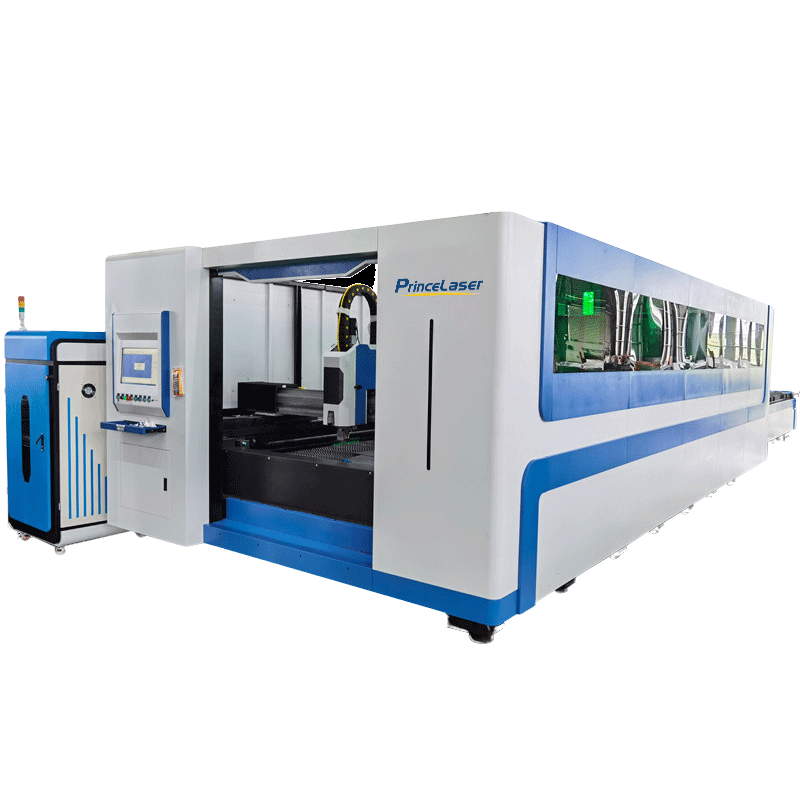

Automatic Coil Feed fiber Lase...  Big table bigg watts full cove...

Big table bigg watts full cove...  1000W 1500W 2000W 3000W 4000W...

1000W 1500W 2000W 3000W 4000W...  1500W 1KW 2KW 3KW Fiber laser ...

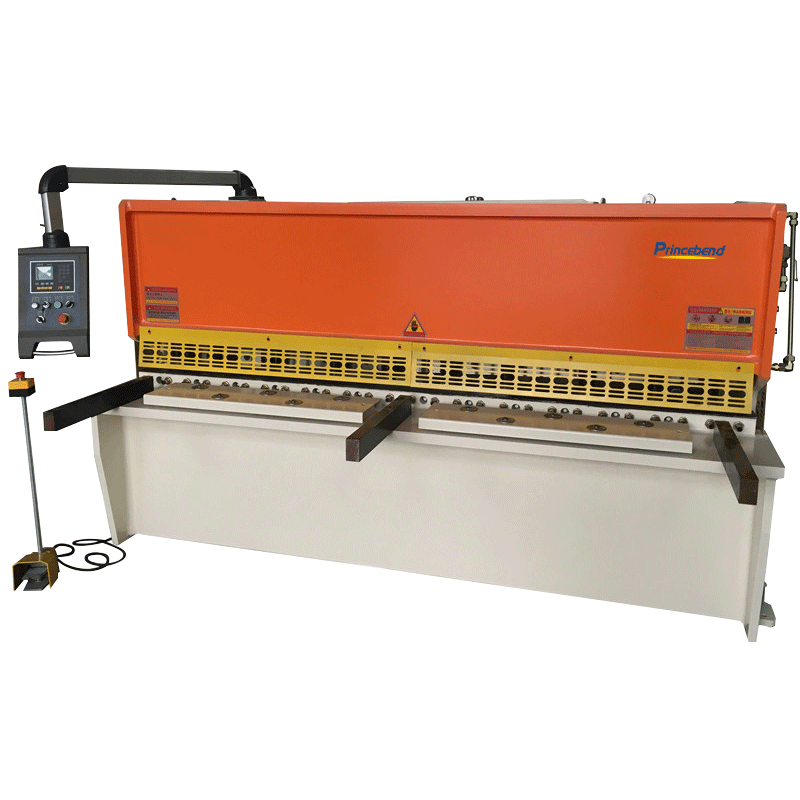

1500W 1KW 2KW 3KW Fiber laser ...  Hydraulic Swing Beam Metal she...

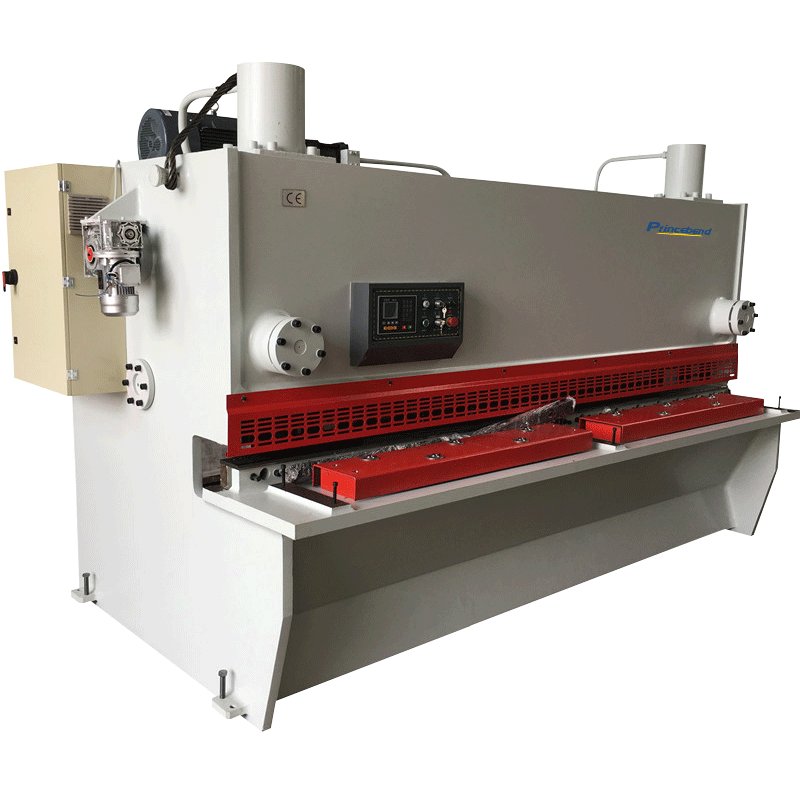

Hydraulic Swing Beam Metal she...  Cnc hyraulic shearing machine

Cnc hyraulic shearing machine  Sheet metal hydraulic guilloti...

Sheet metal hydraulic guilloti...  heavy duty type shearing machi...

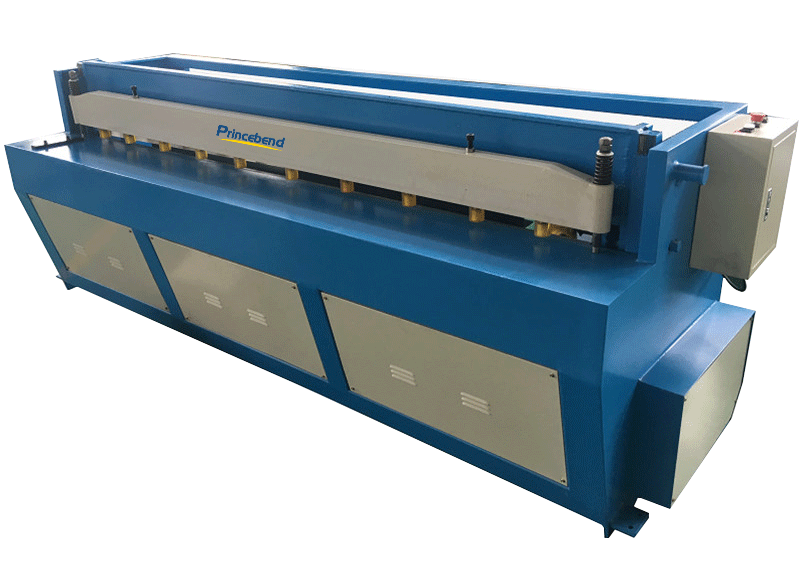

heavy duty type shearing machi...  Metal Electric Shearing Machin...

Metal Electric Shearing Machin...  2500mm Automatic Panel Bender...

2500mm Automatic Panel Bender...  15 Axis Sheet Metal Bending Ce...

15 Axis Sheet Metal Bending Ce...  Automatic Panel Bender Metal P...

Automatic Panel Bender Metal P...  W12 4 rolls plate bending mach...

W12 4 rolls plate bending mach...  NC hydraulic W11S 3 roller ste...

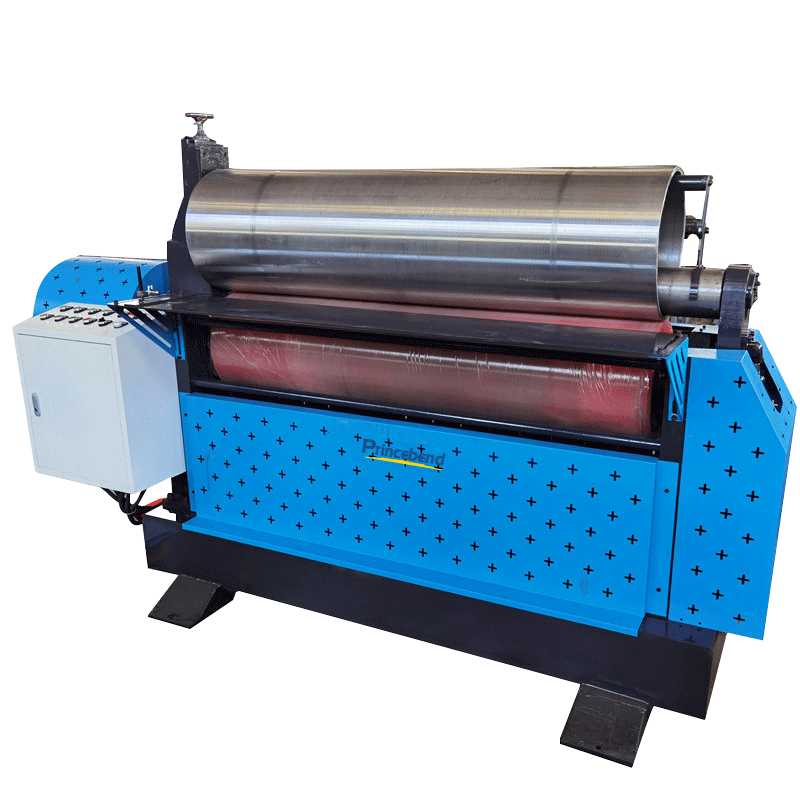

NC hydraulic W11S 3 roller ste...  Hydraulic cnc 4 rolls bending ...

Hydraulic cnc 4 rolls bending ...  Heavy metal sheet Four rollers...

Heavy metal sheet Four rollers...  Heavy duty type Two roller pla...

Heavy duty type Two roller pla...