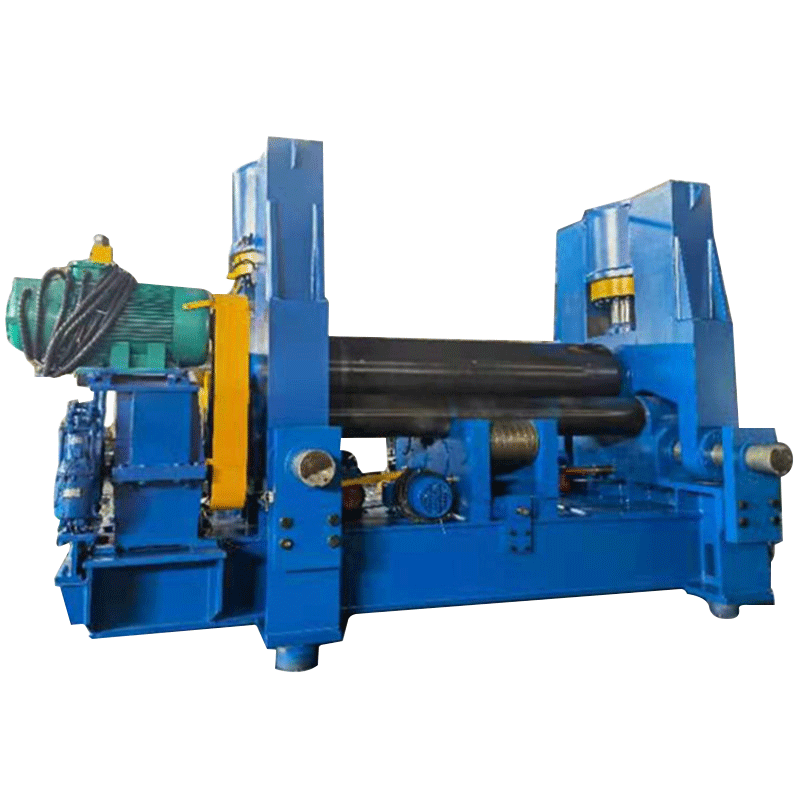

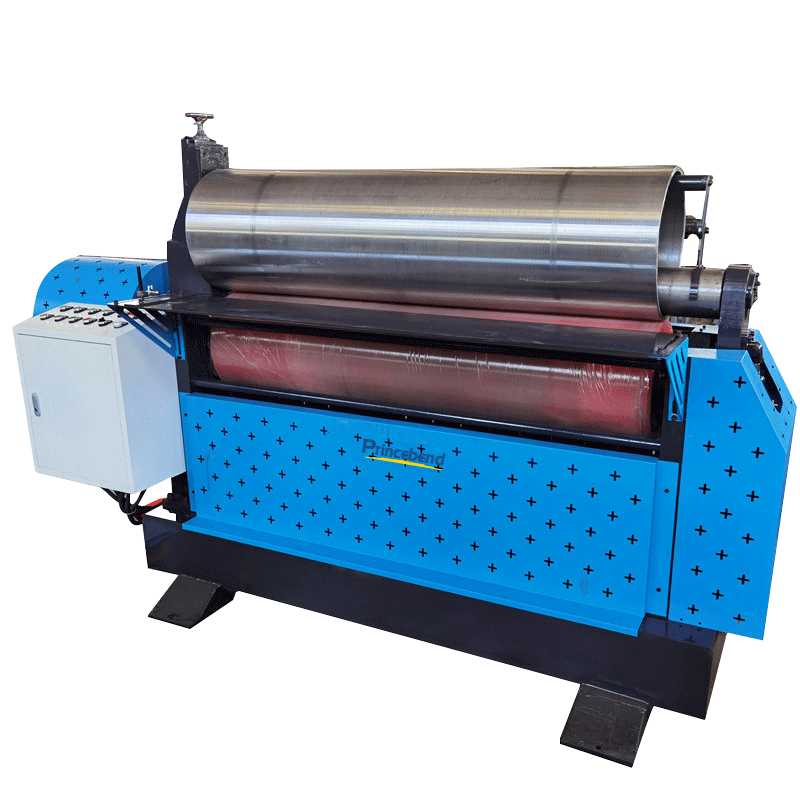

Heavy duty plate 3 rollers hydraulic steel plate rolling machine iron metal round bending machine

Heavy duty plate 3 rollers hydraulic steel plate rolling machine iron metal round bending machine.Technical sheets

Heavy duty plate 3 rollers hydraulic steel plate rolling machine iron metal round bending machine

Technical sheets:

W11S-50×3200

Max. Thickness of plate 50mm(CS),40mm(SS)

Max. Pre-bending thickness 40mm(CS),32mm(SS)

Max. Width of plate 3200mm

The length of working rolls 3300mm

Top pressure 540T

Up roller diameter 600mm

Bottom roller diameter 340mm

Central distance 610mm

Support roller 340mm

Support roller group one group (4 pieces)

Minimum bending diameter 1200mm

Yield limit 245MPa

Bending speed 4m/min

Main motor 55KW

1.The Feature of Hydraulic Plate Rolling machine :

-The machine widely used in petroleum, chemical industry, cement, boiler, shipbuilding, aviation, water conservancy, power transmission towers and other machinery and equipment. Its working principle is rotating bending deformation.

– A cylinder can be rolled, including the pre-bending of both ends, feeding the plate forward through the rolls, one time only. The operator should find one only position for each side roll, to get part finished. Permanent lubrication technology(bearing life period without refueling).

2.The whole structure of Hydraulic Plate rolling machine :

-Totally European design,streamlined looking,frames of our machines are fabricated, welded steel (ST-52). Roll shafts, materials and bearings used in production are European quality. Also the torque limit of the machines is very high. NC playback and CNC graphic control systems are available as optional accessory.

– The main structure of the equipment includes upper roller, lower roller and horizontal movement mechanism, supporting mechanism,main drive mechanism,downturn system, left and right machine frame, chassis and balance mechanism, hydraulic and electrical control systems.

– It allows for excellent roundness, thanks to the Planetary movement of the side rolls (PRIMA patent), moving them to the center of the machine (the tightest geometry available), compared to the inclined linear guides of other brands that, especially on large diameters, move farther away from the central roll and the plate clamping.clamping pressure is adjustable(no-existent skidding,productivity is 80% than three roller plate rolling machine)

#plate rolling bending machine #plate bending rolling machine

#plate bending rolling machine 50 m #rolling plate bending machine

250ton 4000mm hydraulic CNC pr...

250ton 4000mm hydraulic CNC pr...  80ton 2550mm hydraulic CNC pre...

80ton 2550mm hydraulic CNC pre...  Delem CNC Synchronized Press B...

Delem CNC Synchronized Press B...  Amada type RG60T/2000mm hydrau...

Amada type RG60T/2000mm hydrau...  NC Hydraulic press brake bendi...

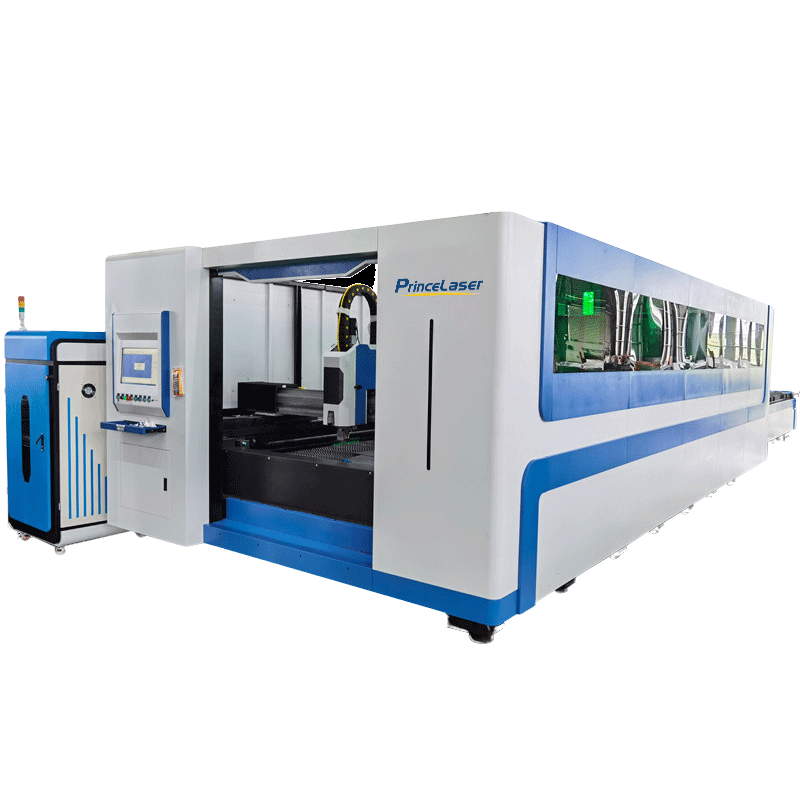

NC Hydraulic press brake bendi...  3000W 4000w Raycus exchangeabl...

3000W 4000w Raycus exchangeabl...  Automatic Coil Feed fiber Lase...

Automatic Coil Feed fiber Lase...  Big table bigg watts full cove...

Big table bigg watts full cove...  1000W 1500W 2000W 3000W 4000W...

1000W 1500W 2000W 3000W 4000W...  1500W 1KW 2KW 3KW Fiber laser ...

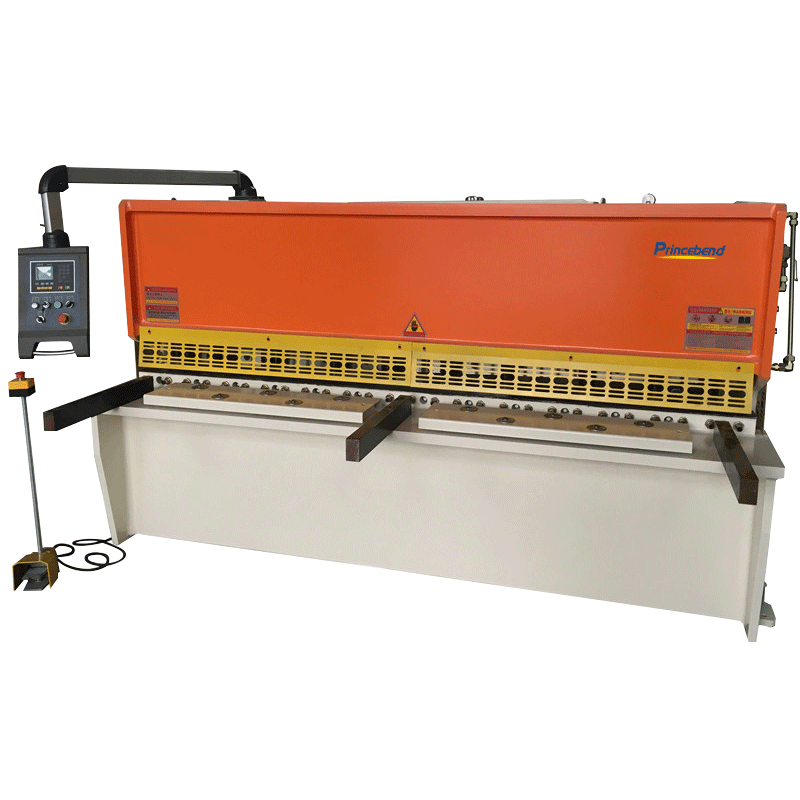

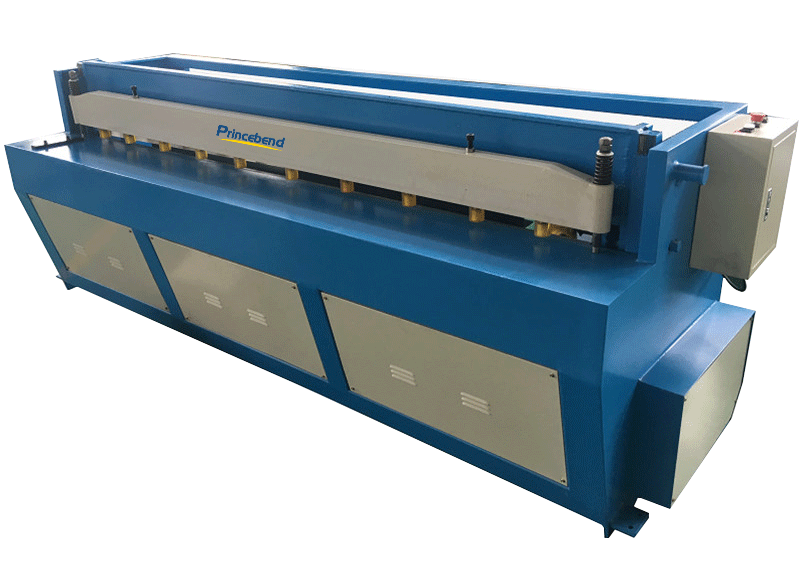

1500W 1KW 2KW 3KW Fiber laser ...  Hydraulic Swing Beam Metal she...

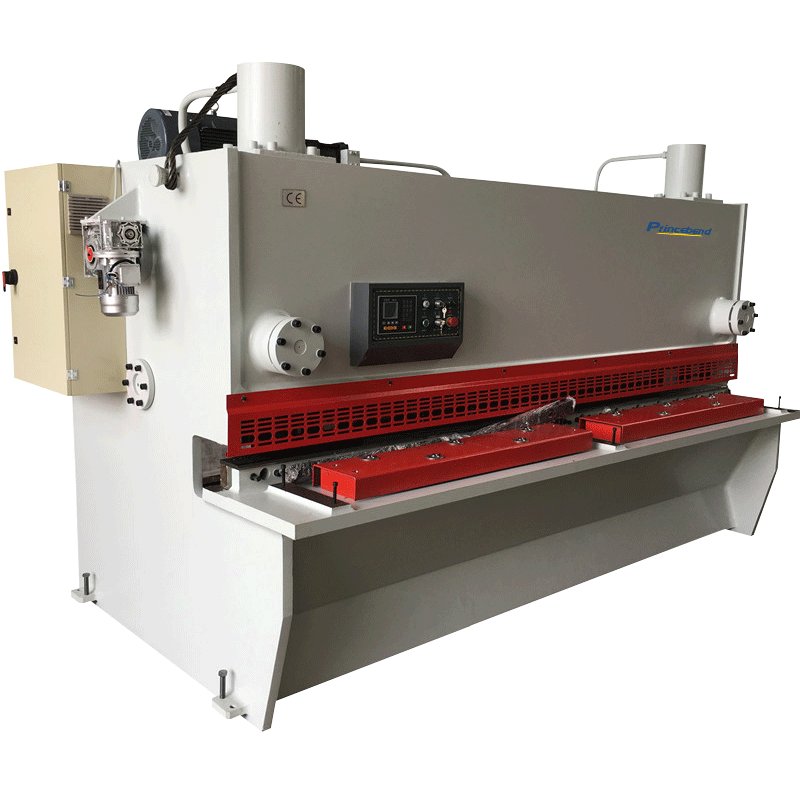

Hydraulic Swing Beam Metal she...  Cnc hyraulic shearing machine

Cnc hyraulic shearing machine  Sheet metal hydraulic guilloti...

Sheet metal hydraulic guilloti...  heavy duty type shearing machi...

heavy duty type shearing machi...  Metal Electric Shearing Machin...

Metal Electric Shearing Machin...  2500mm Automatic Panel Bender...

2500mm Automatic Panel Bender...  15 Axis Sheet Metal Bending Ce...

15 Axis Sheet Metal Bending Ce...  Automatic Panel Bender Metal P...

Automatic Panel Bender Metal P...  W12 4 rolls plate bending mach...

W12 4 rolls plate bending mach...  NC hydraulic W11S 3 roller ste...

NC hydraulic W11S 3 roller ste...  Hydraulic cnc 4 rolls bending ...

Hydraulic cnc 4 rolls bending ...  Heavy metal sheet Four rollers...

Heavy metal sheet Four rollers...  Heavy duty type Two roller pla...

Heavy duty type Two roller pla...